鼓式凸轮式选换挡执行机构效率分析.docx

快乐****蜜蜂

在线预览结束,喜欢就下载吧,查找使用更方便

相关资料

鼓式凸轮式选换挡执行机构效率分析.docx

鼓式凸轮式选换挡执行机构效率分析Title:EfficiencyAnalysisofDrum-ShapedandCam-ShapedShiftingMechanismsinTransmissionSystemsIntroduction:Inthefieldofautomotiveengineering,transmissionsystemsplayacrucialroleinensuringefficientpowertransferfromtheenginetothewheels.Theshifting

机械式自动变速器选换挡执行机构.pdf

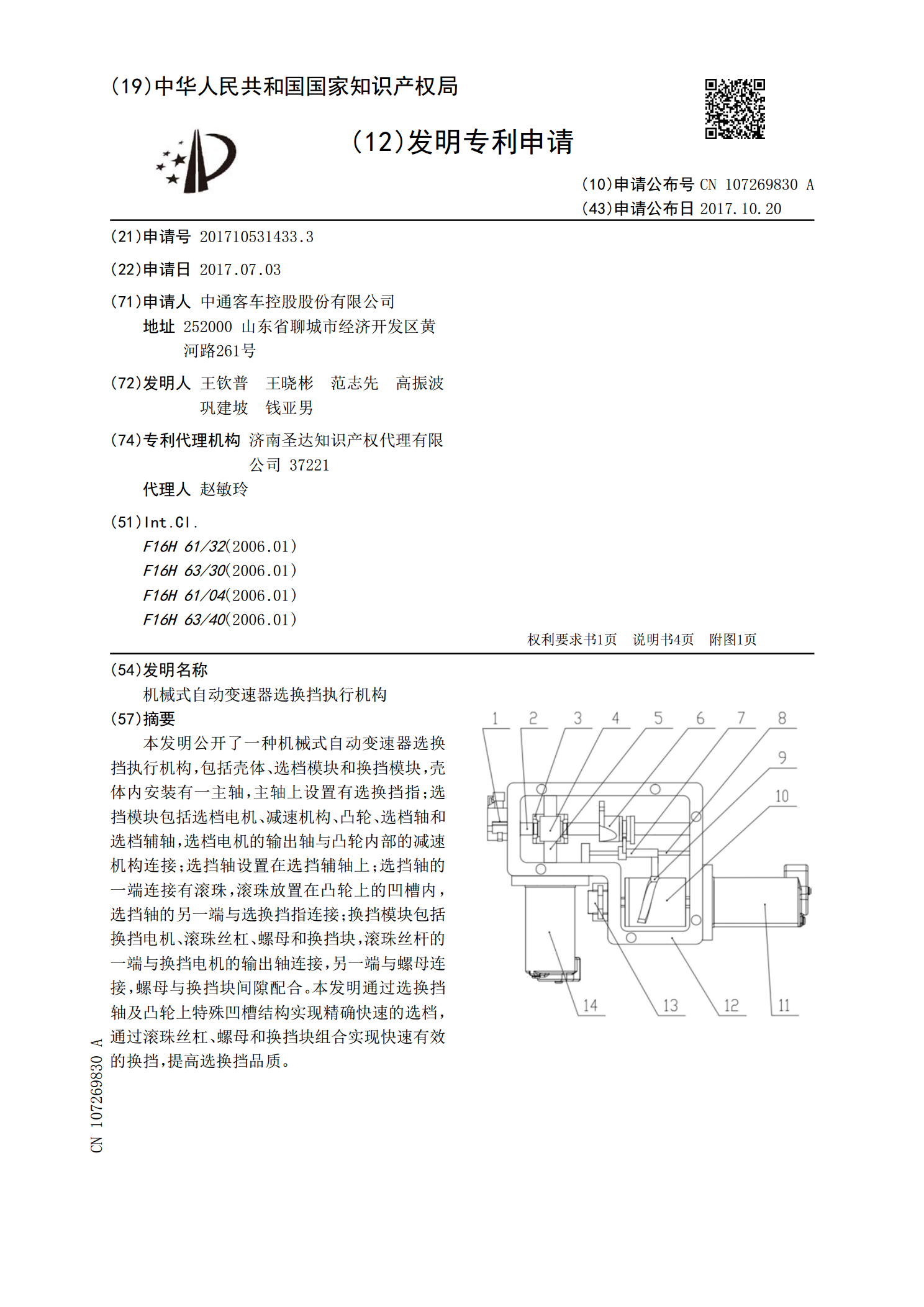

本发明公开了一种机械式自动变速器选换挡执行机构,包括壳体、选档模块和换挡模块,壳体内安装有一主轴,主轴上设置有选换挡指;选挡模块包括选档电机、减速机构、凸轮、选档轴和选档辅轴,选档电机的输出轴与凸轮内部的减速机构连接;选挡轴设置在选挡辅轴上;选挡轴的一端连接有滚珠,滚珠放置在凸轮上的凹槽内,选挡轴的另一端与选换挡指连接;换挡模块包括换挡电机、滚珠丝杠、螺母和换挡块,滚珠丝杆的一端与换挡电机的输出轴连接,另一端与螺母连接,螺母与换挡块间隙配合。本发明通过选换挡轴及凸轮上特殊凹槽结构实现精确快速的选档,通过滚

电控机械式自动变速箱选换挡执行机构.pdf

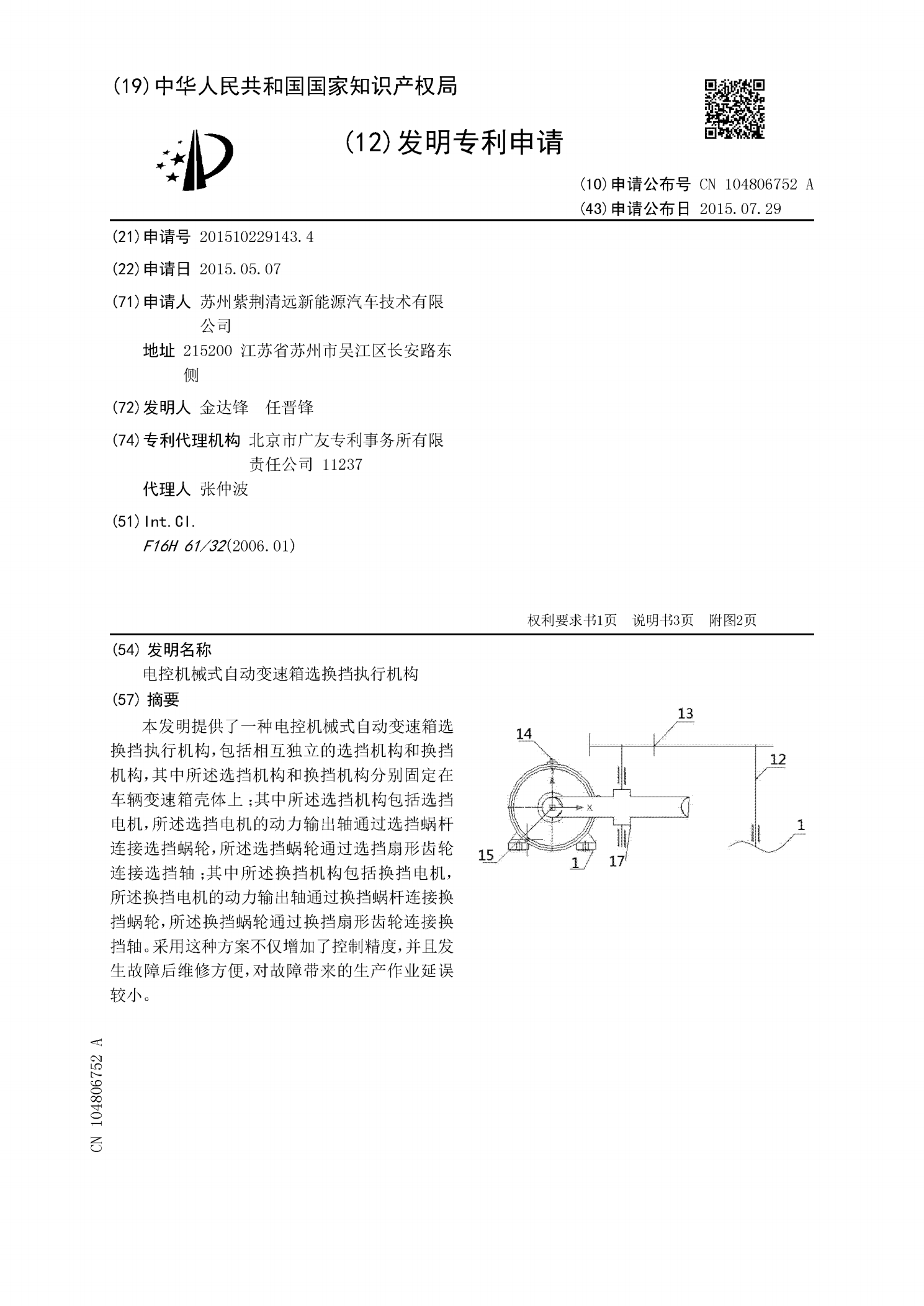

本发明提供了一种电控机械式自动变速箱选换挡执行机构,包括相互独立的选挡机构和换挡机构,其中所述选挡机构和换挡机构分别固定在车辆变速箱壳体上;其中所述选挡机构包括选挡电机,所述选挡电机的动力输出轴通过选挡蜗杆连接选挡蜗轮,所述选挡蜗轮通过选挡扇形齿轮连接选挡轴;其中所述换挡机构包括换挡电机,所述换挡电机的动力输出轴通过换挡蜗杆连接换挡蜗轮,所述换挡蜗轮通过换挡扇形齿轮连接换挡轴。采用这种方案不仅增加了控制精度,并且发生故障后维修方便,对故障带来的生产作业延误较小。

一种选换挡执行机构.pdf

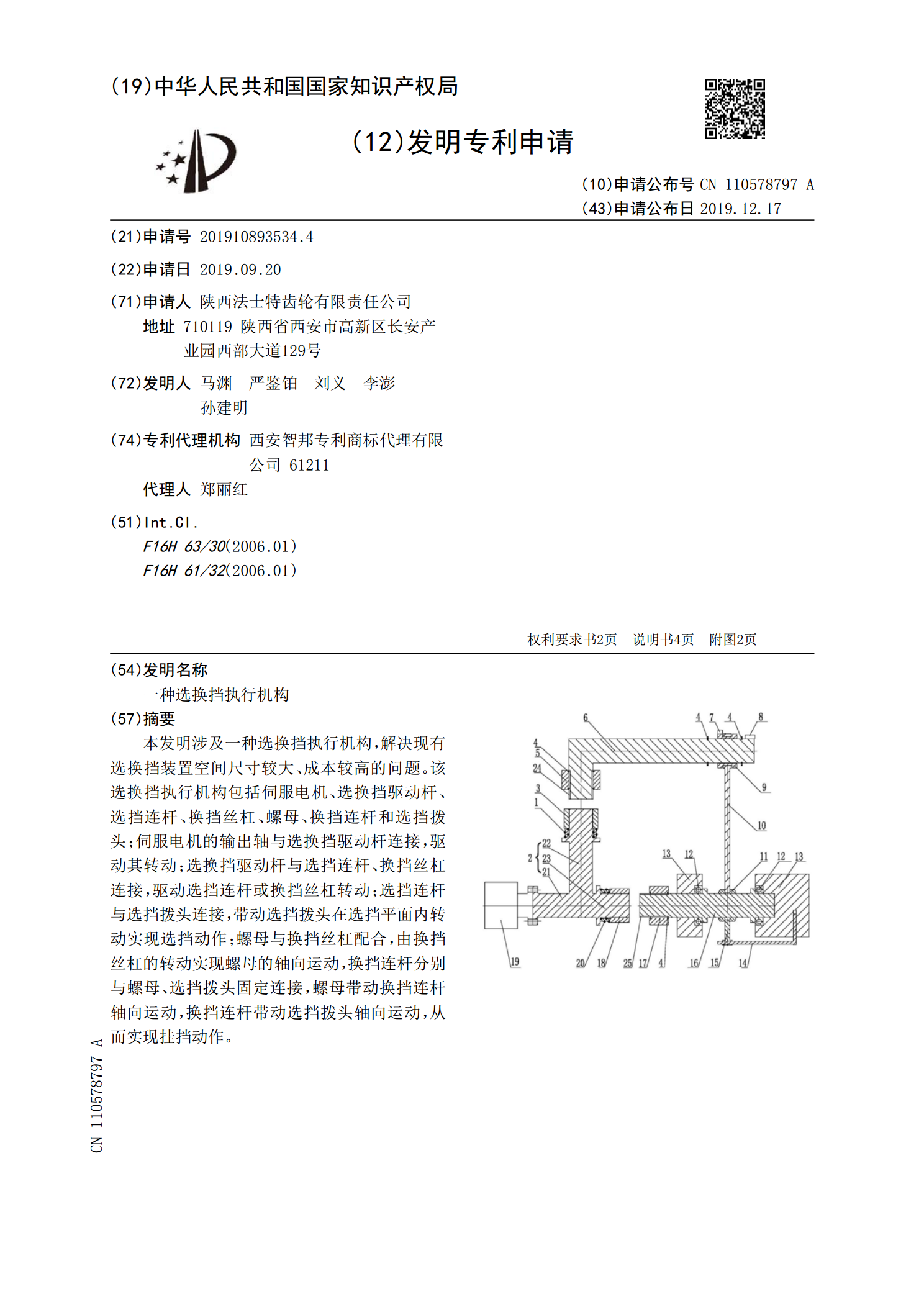

本发明涉及一种选换挡执行机构,解决现有选换挡装置空间尺寸较大、成本较高的问题。该选换挡执行机构包括伺服电机、选换挡驱动杆、选挡连杆、换挡丝杠、螺母、换挡连杆和选挡拨头;伺服电机的输出轴与选换挡驱动杆连接,驱动其转动;选换挡驱动杆与选挡连杆、换挡丝杠连接,驱动选挡连杆或换挡丝杠转动;选挡连杆与选挡拨头连接,带动选挡拨头在选挡平面内转动实现选挡动作;螺母与换挡丝杠配合,由换挡丝杠的转动实现螺母的轴向运动,换挡连杆分别与螺母、选挡拨头固定连接,螺母带动换挡连杆轴向运动,换挡连杆带动选挡拨头轴向运动,从而实现挂挡

一种选换挡执行机构.pdf

本发明提出一种选换挡执行机构,包括选换挡轴,所述选换挡执行机构还包括固定设置在所述选换挡轴上的第一选换挡结构和第二选换挡结构,以及五个拨叉叉口,所述第一选换挡结构和所述第二选换挡结构分别包括退挡凸轮和换挡指,所述五个拨叉叉口设置成可分别与所述第一选换挡结构和所述第二选换挡结构配合的两组。采用这种选换挡执行机构,适用于具有五个同步器的变速器,并且选换挡轴的轴向行程最短。