纯钛箔材表面微裂纹研究.docx

快乐****蜜蜂

在线预览结束,喜欢就下载吧,查找使用更方便

相关资料

纯钛箔材表面微裂纹研究.docx

纯钛箔材表面微裂纹研究摘要:纯钛箔材是一种重要的材料,在航空、航天、核能、化工等领域有着广泛的应用。然而,在其制造过程中,会出现一些微小的裂纹。本论文采用光学显微镜和电子显微镜等手段,对纯钛箔材表面微裂纹进行了研究。通过对拓扑形貌和电子结构的观察,分析了裂纹的产生原因,并提出了预防裂纹产生的方案。这些结果对纯钛箔材的制造和应用具有重要意义。关键词:纯钛箔材、微裂纹、电子显微镜、拓扑形貌IntroductionPuretitaniumfoiliswidelyusedinmanyfieldsduetoitsh

纯钛材与大变形纯钛材微弧氧化膜层的力学性能研究.docx

纯钛材与大变形纯钛材微弧氧化膜层的力学性能研究纯钛材与大变形纯钛材微弧氧化膜层的力学性能研究摘要:钛材料因其良好的力学性能和优异的耐腐蚀性能而在工业领域中广泛应用。而微弧氧化是一种常见的表面处理方法,可以提高钛材料的硬度和耐磨性。本研究旨在研究纯钛材料与大变形纯钛材料微弧氧化膜层的力学性能。实验结果表明,在大变形条件下,钛材料的强度和韧性都有所提高。微弧氧化膜层可以进一步提高钛材料的硬度和耐磨性。此外,经过微弧氧化处理后的钛材料还具有较好的抗腐蚀性能。综上所述,纯钛材料与大变形纯钛材料微弧氧化膜层的力学性

一种宽幅纯钛箔材卷带制备方法.pdf

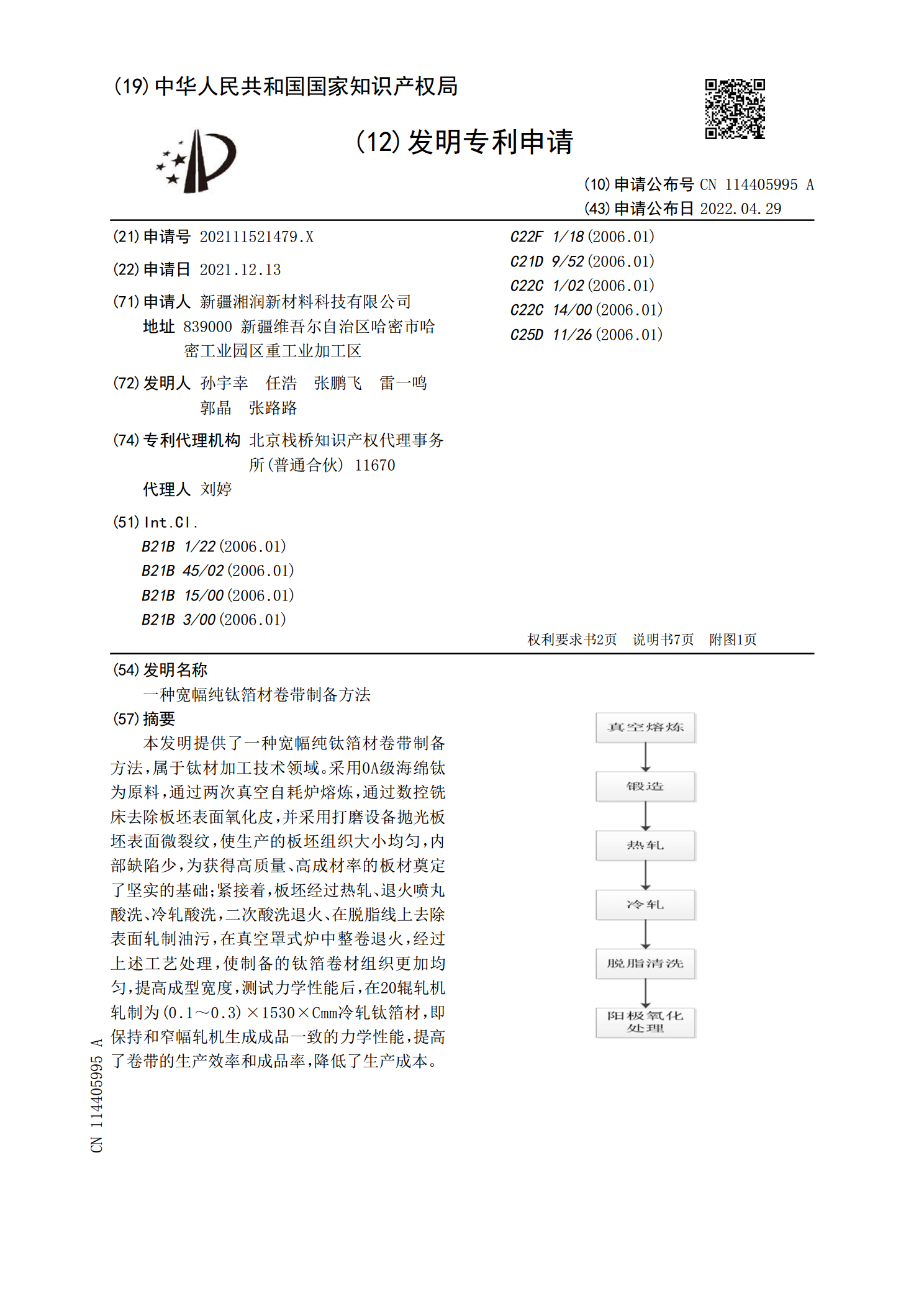

本发明提供了一种宽幅纯钛箔材卷带制备方法,属于钛材加工技术领域。采用0A级海绵钛为原料,通过两次真空自耗炉熔炼,通过数控铣床去除板坯表面氧化皮,并采用打磨设备抛光板坯表面微裂纹,使生产的板坯组织大小均匀,内部缺陷少,为获得高质量、高成材率的板材奠定了坚实的基础;紧接着,板坯经过热轧、退火喷丸酸洗、冷轧酸洗,二次酸洗退火、在脱脂线上去除表面轧制油污,在真空罩式炉中整卷退火,经过上述工艺处理,使制备的钛箔卷材组织更加均匀,提高成型宽度,测试力学性能后,在20辊轧机轧制为(0.1~0.3)×1530×Cmm冷轧

冷轧钛箔材工艺.pdf

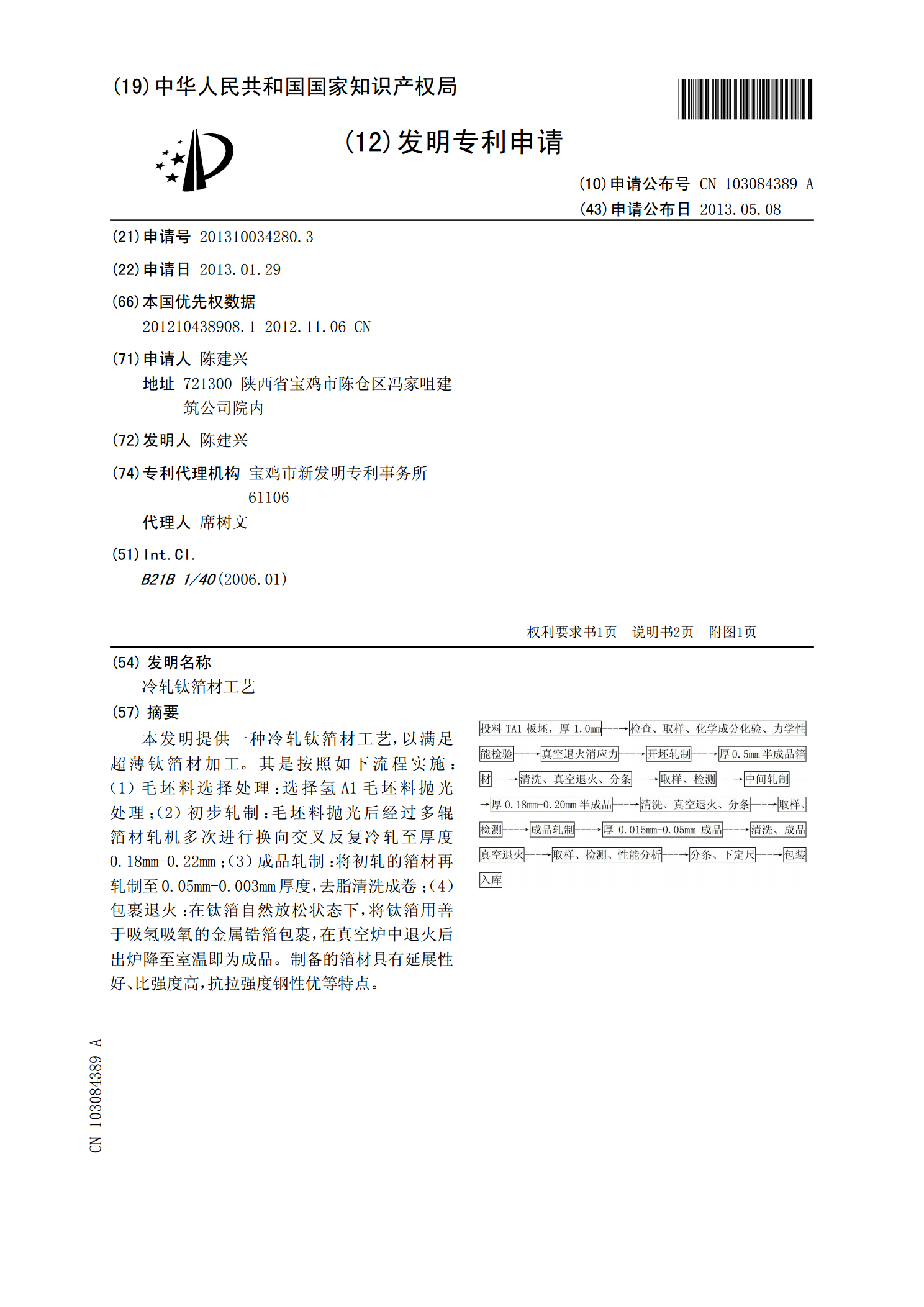

本发明提供一种冷轧钛箔材工艺,以满足超薄钛箔材加工。其是按照如下流程实施:(1)毛坯料选择处理:选择氢A1毛坯料抛光处理;(2)初步轧制:毛坯料抛光后经过多辊箔材轧机多次进行换向交叉反复冷轧至厚度0.18mm-0.22mm;(3)成品轧制:将初轧的箔材再轧制至0.05mm-0.003mm厚度,去脂清洗成卷;(4)包裹退火:在钛箔自然放松状态下,将钛箔用善于吸氢吸氧的金属锆箔包裹,在真空炉中退火后出炉降至室温即为成品。制备的箔材具有延展性好、比强度高,抗拉强度钢性优等特点。

不同电参数对微弧氧化纯钛表面影响的研究.docx

不同电参数对微弧氧化纯钛表面影响的研究摘要:微弧氧化是一种先进的表面处理技术,可以在金属表面形成无色、有硬度、耐腐蚀性能良好的陶瓷涂层。本文以纯钛为研究对象,探讨了不同电参数对微弧氧化纯钛表面的影响。通过调整电压、电流、处理时间等参数,制备了不同性质的涂层,并对其进行了表征和分析,以寻求最优的微弧氧化工艺条件。关键词:微弧氧化,纯钛,电参数,涂层Abstract:Micro-arcoxidationisanadvancedsurfacetreatmenttechnology,whichcanformcer