含Er的Al-Mg合金焊丝制备及其组织和机械性能的综述报告.docx

快乐****蜜蜂

在线预览结束,喜欢就下载吧,查找使用更方便

相关资料

含Er的Al-Mg合金焊丝制备及其组织和机械性能的综述报告.docx

含Er的Al-Mg合金焊丝制备及其组织和机械性能的综述报告摘要:本文讨论了含Er的Al-Mg合金焊丝的制备方法、组织和机械性能的研究现状。Er的加入可以明显改善焊接接头的性能。文章探讨了Er含量、热处理和焊接条件对焊丝组织和性能的影响,重点讨论了焊接接头的力学性能、微观组织和断口形貌。本文还总结了该领域的研究进展和未来发展方向。关键词:含Er的Al-Mg合金焊丝;制备方法;组织和机械性能;热处理;焊接条件;力学性能;微观组织;断口形貌IntroductionAluminumanditsalloysarew

AlMg合金中含Er相的热力学计算研究的综述报告.docx

AlMg合金中含Er相的热力学计算研究的综述报告引言AlMg合金是一种常用的轻质结构材料,具有高强度、高耐腐蚀性、可塑性好和良好的热处理性能等优点。其中,添加稀土元素Er可以显著提高AlMg合金的抗拉、屈服和延展性能,并降低材料的晶粒尺寸。因此,研究AlMg-Er合金的热力学计算是非常重要的。研究方法本文通过查阅大量相关文献,对AlMg-Er合金中Er相的热力学计算研究进行了综述。热力学计算主要涉及自由能、热力学平衡和相变等内容,其中相变是最重要的热力学过程之一。根据相变方式的不同,可以将AlMg-Er合

一种耐蚀Al-Mg-Er-Zr合金焊丝及其制备方法.pdf

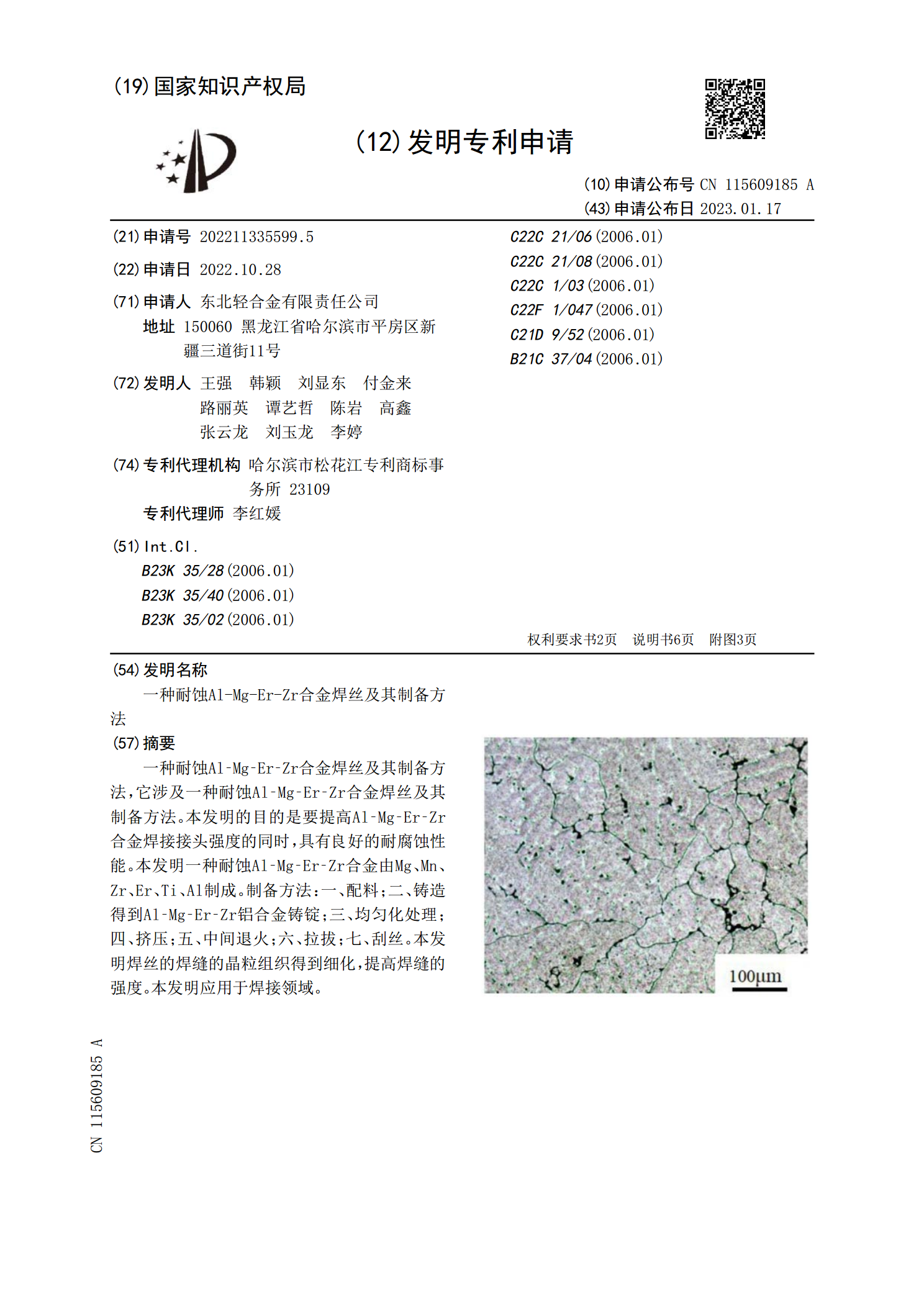

一种耐蚀Al‑Mg‑Er‑Zr合金焊丝及其制备方法,它涉及一种耐蚀Al‑Mg‑Er‑Zr合金焊丝及其制备方法。本发明的目的是要提高Al‑Mg‑Er‑Zr合金焊接接头强度的同时,具有良好的耐腐蚀性能。本发明一种耐蚀Al‑Mg‑Er‑Zr合金由Mg、Mn、Zr、Er、Ti、Al制成。制备方法:一、配料;二、铸造得到Al‑Mg‑Er‑Zr铝合金铸锭;三、均匀化处理;四、挤压;五、中间退火;六、拉拔;七、刮丝。本发明焊丝的焊缝的晶粒组织得到细化,提高焊缝的强度。本发明应用于焊接领域。

一种铝合金焊丝制备方法及其制备的铝合金焊丝.pdf

本发明提供了一种铝合金焊丝制备方法及其制备的铝合金焊丝,方法包括:将铝锭加入到感应电炉中,熔化并升温至850℃~880℃,然后将感应电炉调整为搅拌模式;将氟钛酸钾、氟硼酸钾、铌粉混合料加入感应电炉内,反应后倾倒出合金表面上的熔盐;加入氟化钙清理合金表面剩余熔盐,清理完毕后,将合金温度降至800℃‑830℃,用旋转除气机通氩气进行精炼除气;精炼除气完毕清理合金表面浮渣后,将合金连铸连轧连挤成

含钎剂铝合金焊丝的制备及其性能研究的开题报告.docx

含钎剂铝合金焊丝的制备及其性能研究的开题报告【题目】含钎剂铝合金焊丝的制备及其性能研究【研究背景】铝合金是广泛应用于航空、汽车、电子等领域的重要材料,而铝合金的焊接加工是其应用的重要环节之一。传统的铝合金焊接方式多采用氩弧焊和TIG焊,但这些焊接方式存在着设备成本高、效率低和采用气体保护焊时对环境的污染等问题。因此,研究铝合金焊接的新技术和新材料具有重要的现实意义。钎焊是一种新的焊接方式,优点是操作简便、能节省成本并且对环境无污染。其中,含钎剂铝合金焊丝是一种重要的材料,在钎焊中具有较高的应用价值。【研究