一种高韧性含硼模具钢及其制备方法.pdf

一吃****新冬

亲,该文档总共13页,到这已经超出免费预览范围,如果喜欢就直接下载吧~

相关资料

一种高韧性含硼模具钢及其制备方法.pdf

本发明公开了一种高韧性含硼模具钢及其制造方法,质量百分比:0.25~0.5%?C,0.8~2.4%?Cr,0.3~0.8%?Si,3.1~5.2%?Mn,0.6~2.0%?B,0.3~1.5%?Cu,0.10~0.50%?Ti,?0.05~0.25%?Ca,0.05~0.3%?ReSiMg,?0.02~0.18%?N,0.05~0.3%?Nb,0.30~0.80%?Al,0.04~0.13%K,S<0.03%,?P<0.04%,余量为Fe;采用中频炉熔化至1560~1620℃,将由60~100目的钒铁、钛

高韧性含硼高速钢及其制备方法.pdf

本发明公开了一种高韧性含硼高速钢及其制备方法,质量百分比:0.30~0.6%?C,3.5~5.0%?Cr,0.4~1.15%?Si,3.4~5.2%?Mn,0.8~2.5%?B,0.9~2.8%?Mo,1.0~3.2%?W,0.5~1.5%?V,0.6~1.8%?Cu,0.5~1.2%?Ti,0.05~0.20%?Ca,0.05~0.25%?Ce,0.05~0.2%?Y,0.02~0.18%?N,0.05~0.3%Nb,0.12~0.25%Mg,0.06~0.15Ba,0.04~0.13%K,S<0.03

一种高韧性含硼高铬耐磨合金及其制备方法.pdf

本发明公开了一种高韧性含硼高铬耐磨合金及其制备方法,质量百分比:0.20~0.6%C,15~20%Cr,0.5~1.10%Si,3.5~6.0%Mn,0.4~2.3%B,0.4~1.5%Cu,0.3~1.2%Ti,0.10~1.0%V,0.05~0.3%Nb,0.05~0.10%Al,0.10~0.25%Ca,0.05~0.2%Y,0.05~0.3%Ce,0.04~0.20%N,0.05~0.15%K,S<0.03%,P<0.04%,余量为Fe;采用中频炉熔化至1560~1620℃,将由60~100目的钒

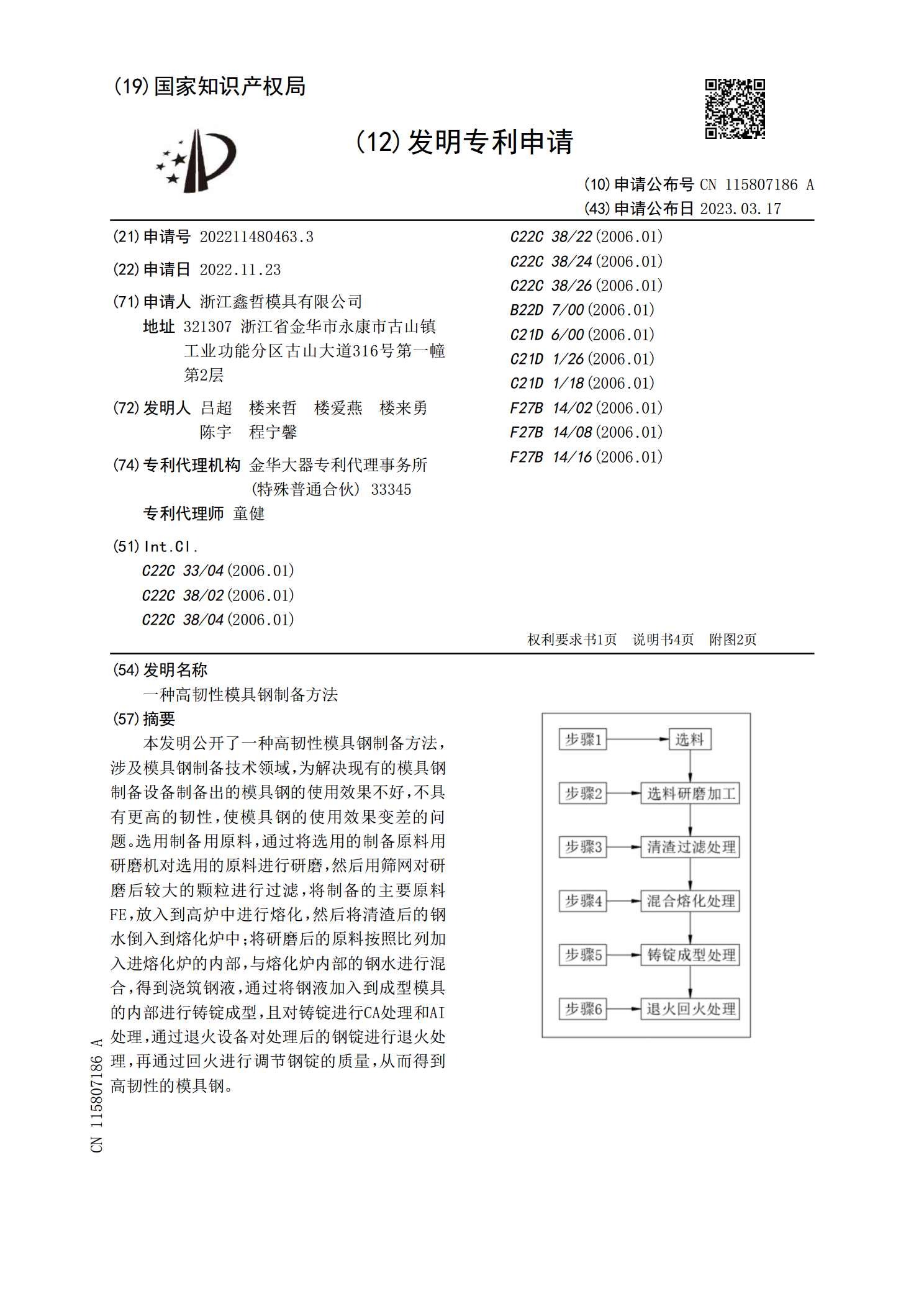

一种高韧性模具钢制备方法.pdf

本发明公开了一种高韧性模具钢制备方法,涉及模具钢制备技术领域,为解决现有的模具钢制备设备制备出的模具钢的使用效果不好,不具有更高的韧性,使模具钢的使用效果变差的问题。选用制备用原料,通过将选用的制备原料用研磨机对选用的原料进行研磨,然后用筛网对研磨后较大的颗粒进行过滤,将制备的主要原料FE,放入到高炉中进行熔化,然后将清渣后的钢水倒入到熔化炉中;将研磨后的原料按照比列加入进熔化炉的内部,与熔化炉内部的钢水进行混合,得到浇筑钢液,通过将钢液加入到成型模具的内部进行铸锭成型,且对铸锭进行CA处理和AI处理,通

一种含硼模具钢及其热处理方法.pdf

本发明提供了一种含硼模具钢及其热处理方法,其化学成分及其质量百分比为:C:0.35~0.45%;B:1.2-1.6%;Al:0.6-0.8%;Cr:1.8-2.5%;Mo:0.4-0.6%;Ni:0.3-0.5%;Ti:0.05-0.30%;Ta:0.02-0.15%;Nb:0.05-0.20%;Mn:0.5-1.0%;Si:0.3-0.5%;Y:0.03-0.06%;Ca:0.008-0.020%;余量为Fe,其中,0.30炉内升温至880~920℃后保温4~8小时,接着,在1050~1080℃继续加热