基于ABAQUS的铝镁层状复合材料SLM热源优化.docx

快乐****蜜蜂

在线预览结束,喜欢就下载吧,查找使用更方便

相关资料

基于ABAQUS的铝镁层状复合材料SLM热源优化.docx

基于ABAQUS的铝镁层状复合材料SLM热源优化Title:OptimizationofHeatSourceforSelectiveLaserMeltingofAluminum-MagnesiumLayeredCompositeMaterialUsingABAQUSAbstract:SelectiveLaserMelting(SLM)isapromisingadditivemanufacturingtechniquethatenablestheproductionofcomplex,high-perfor

基于SLM的纯铝AM60层状复合材料的温度场模拟.docx

基于SLM的纯铝AM60层状复合材料的温度场模拟基于SLM的纯铝AM60层状复合材料的温度场模拟摘要:随着先进制造技术的发展,选择性激光熔化(SLM)作为一种数字化打印技术,被广泛用于复杂金属部件的制造。本文研究了基于SLM的纯铝AM60层状复合材料的温度场模拟。通过数值模拟分析,我们研究了SLM过程中的温度分布和传热特性,以及对于材料性能的影响。我们的研究结果可以为纯铝AM60复合材料的SLM加工提供指导和参考。1.引言选择性激光熔化(SLM)是一种先进的3D打印技术,它通过激光束将金属粉末层状熔化和固

镁--铝--钽层状复合材料轧制工艺与结合界面的研究的任务书.docx

镁--铝--钽层状复合材料轧制工艺与结合界面的研究的任务书任务书题目:镁--铝--钽层状复合材料轧制工艺与结合界面的研究一、研究背景层状复合材料是由不同材料层堆叠组成的一种新型材料。它的组成、性能以及应用领域十分广泛。镁合金具有密度低、比强度高的特点,但由于容易发生腐蚀、氧化等问题,导致其应用受到限制。铝合金具有优良的耐腐蚀性和加工性能,但密度相对较大。因此,将镁和铝合金进行复合可以充分发挥两者的优点,使得其密度和比强度同时达到较好的表现。钽是一种高强度、高熔点的金属,其与镁和铝的复合可以增强材料的抗拉强

基于Abaqus和modeFRONTIER的复合材料结构优化设计方法.docx

基于Abaqus和modeFRONTIER的复合材料结构优化设计方法随着经济和技术的发展,复合材料结构的应用范围越来越广泛,其具有轻质、高强、耐腐蚀等优点,被广泛应用于航空、汽车、船舶等领域。但是在复合材料结构的设计过程中,需要考虑的因素很多,例如材料的性能特点、外部载荷、结构几何形状等,因此如何进行优化设计成为了一个重要问题。在这种情况下,结合Abaqus和modeFRONTIER的复合材料结构优化设计方法应运而生。Abaqus是一款基于有限元分析的软件,可以对复合材料结构进行建模分析,模拟不同工况下的

镁/铝基层状复合板的制备方法.pdf

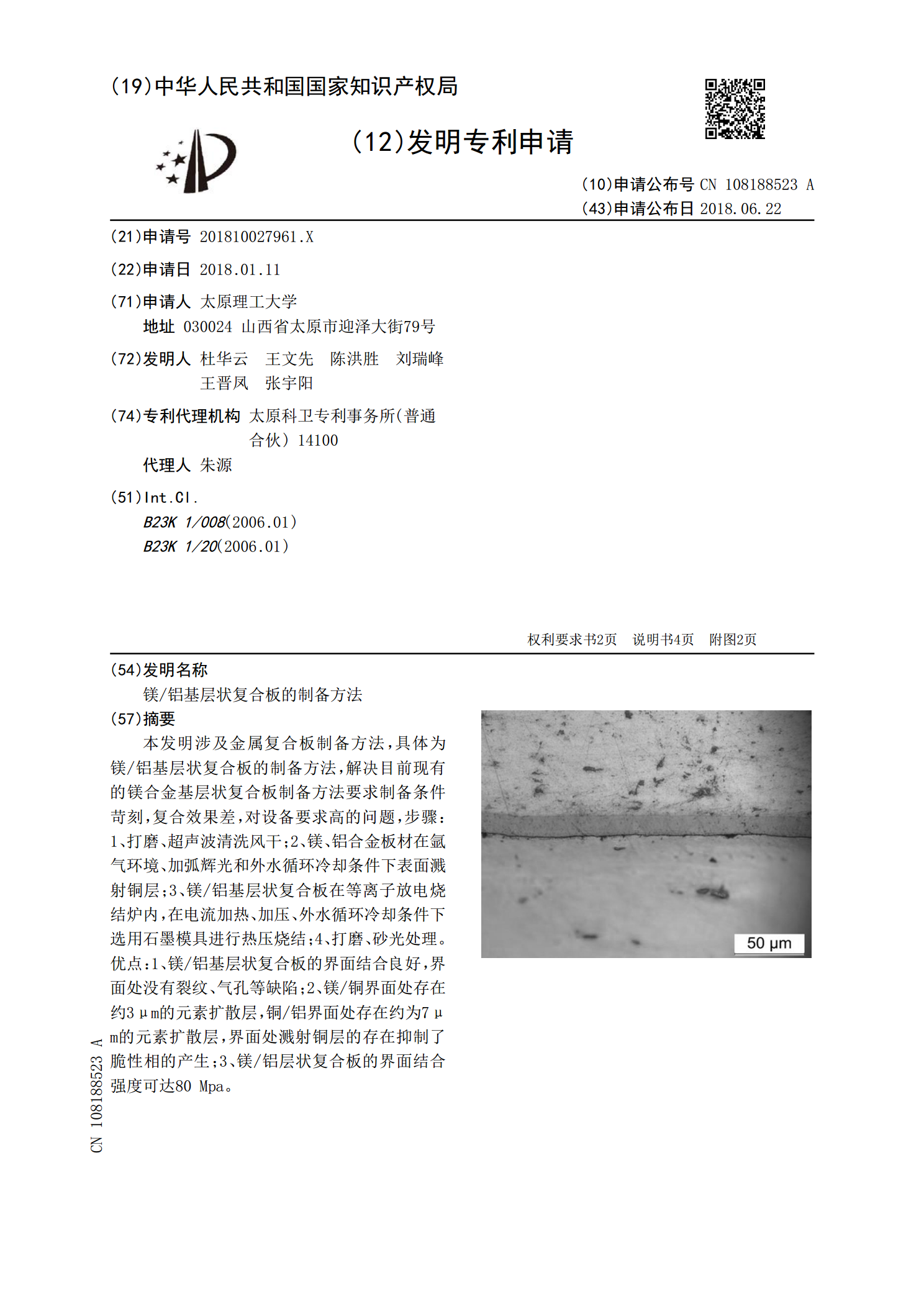

本发明涉及金属复合板制备方法,具体为镁/铝基层状复合板的制备方法,解决目前现有的镁合金基层状复合板制备方法要求制备条件苛刻,复合效果差,对设备要求高的问题,步骤:1、打磨、超声波清洗风干;2、镁、铝合金板材在氩气环境、加弧辉光和外水循环冷却条件下表面溅射铜层;3、镁/铝基层状复合板在等离子放电烧结炉内,在电流加热、加压、外水循环冷却条件下选用石墨模具进行热压烧结;4、打磨、砂光处理。优点:1、镁/铝基层状复合板的界面结合良好,界面处没有裂纹、气孔等缺陷;2、镁/铜界面处存在约3μm的元素扩散层,铜/铝界面