浅析玻璃熔窑寿命影响因素.docx

快乐****蜜蜂

在线预览结束,喜欢就下载吧,查找使用更方便

相关资料

浅析玻璃熔窑寿命影响因素.docx

浅析玻璃熔窑寿命影响因素Title:AnAnalysisofFactorsInfluencingtheServiceLifeofGlassMeltingFurnacesIntroduction:Glassmeltingfurnacesareintegraltotheglassmanufacturingprocess.Theservicelifeofthesefurnacesiscrucialforefficientproductionandcost-effectiveness.Understandingt

玻璃熔制及熔窑---熔窑3.ppt

3.2.1.2热源供给小炉斜碹是组成小炉的重要部位,也是容易被烧损的部位。小炉斜碹的下倾角应视具体情况对待小炉对数:3.2.1.3余热回收部分(1)蓄热室的分类A.连通式蓄热室B.分隔式蓄热室C.半分隔式蓄热室---蓄热室炉条碹以下的烟道以每个小炉分隔,蓄热室本身不分隔。D.二小炉式蓄热室E.二段式蓄热室(2)蓄热室的结构蓄热室顶碹传统的格子砖形式都很难避免结构稳定性差、码砌困难等缺点。目前在浮法玻璃熔窑上使用最多的是筒子砖格子体。炉条碹蓄热室顶碹3.2.2.4排烟供气部分①烟道的布置在分支烟道上设有烟气

玻璃熔窑.pdf

本发明公开了玻璃熔窑,该熔窑包括底板,所述底板顶端活动卡接设置有活动轴,所述活动轴外侧固定设置有第一齿轮,所述活动轴顶端水平固定设置有水平杆,所述水平杆一侧设置有熔化机构,所述底板顶端固定设置有第一箱体,所述第一箱体顶端通过支撑架固定设置有第二箱体。本发明水平杆转动至竖直杆顶端位置时,此时水平杆向下挤压竖直杆,使得限位环挤压第一弹簧,利用第一弹簧弹力使得竖直杆紧贴在第一导电块与第二导电块上,从而使得电磁加热线圈与外接电源连通,直到加热完成后,此时转动使得加热熔化完成后的玻璃被移出,电磁加热线圈重新处于断电

玻璃配合料中的超细粉对熔窑的影响.pdf

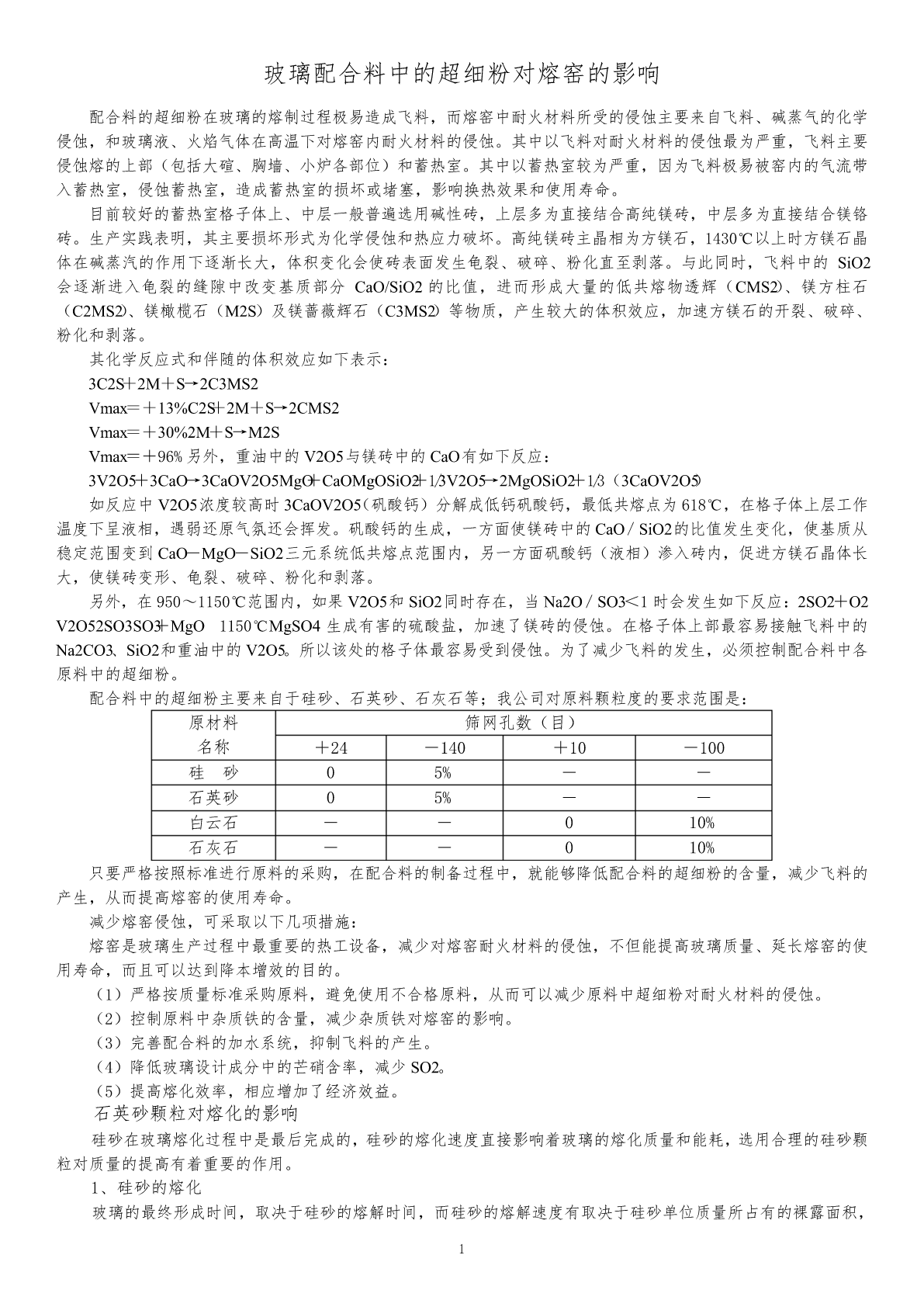

玻璃配合料中的超细粉对熔窑的影响配合料的超细粉在玻璃的熔制过程极易造成飞料,而熔窑中耐火材料所受的侵蚀主要来自飞料、碱蒸气的化学侵蚀,和玻璃液、火焰气体在高温下对熔窑内耐火材料的侵蚀。其中以飞料对耐火材料的侵蚀最为严重,飞料主要侵蚀熔的上部(包括大碹、胸墙、小炉各部位)和蓄热室。其中以蓄热室较为严重,因为飞料极易被窑内的气流带入蓄热室,侵蚀蓄热室,造成蓄热室的损坏或堵塞,影响换热效果和使用寿命。目前较好的蓄热室格子体上、中层一般普遍选用碱性砖,上层多为直接结合高纯镁砖,中层多为直接结合镁铬砖。生产实践表明

寿命周期理论在浮法玻璃熔窑管理中的应用.docx

寿命周期理论在浮法玻璃熔窑管理中的应用标题:寿命周期理论在浮法玻璃熔窑管理中的应用摘要:浮法玻璃熔窑是玻璃制造过程中最关键的设备之一,其管理对于生产效率、产品质量以及安全性具有重要作用。本文探讨了寿命周期理论在浮法玻璃熔窑管理中的应用,包括熔炉设计与规划、设备维护、故障排除和性能改进等方面。通过应用寿命周期理论,可以提升熔窑的整体管理水平,最大限度地延长其使用寿命,实现更高效、稳定、可靠的熔窑操作和生产。1.引言浮法玻璃熔窑是玻璃工业生产过程中最复杂和昂贵的设备之一,其生命周期包含了设计、制造、投入使用、