克林贝格螺旋锥齿轮设计及参数计算.xls

qw****27

亲,该文档总共3页,到这已经超出免费预览范围,如果喜欢就直接下载吧~

相关资料

克林贝格螺旋锥齿轮设计及参数计算.xls

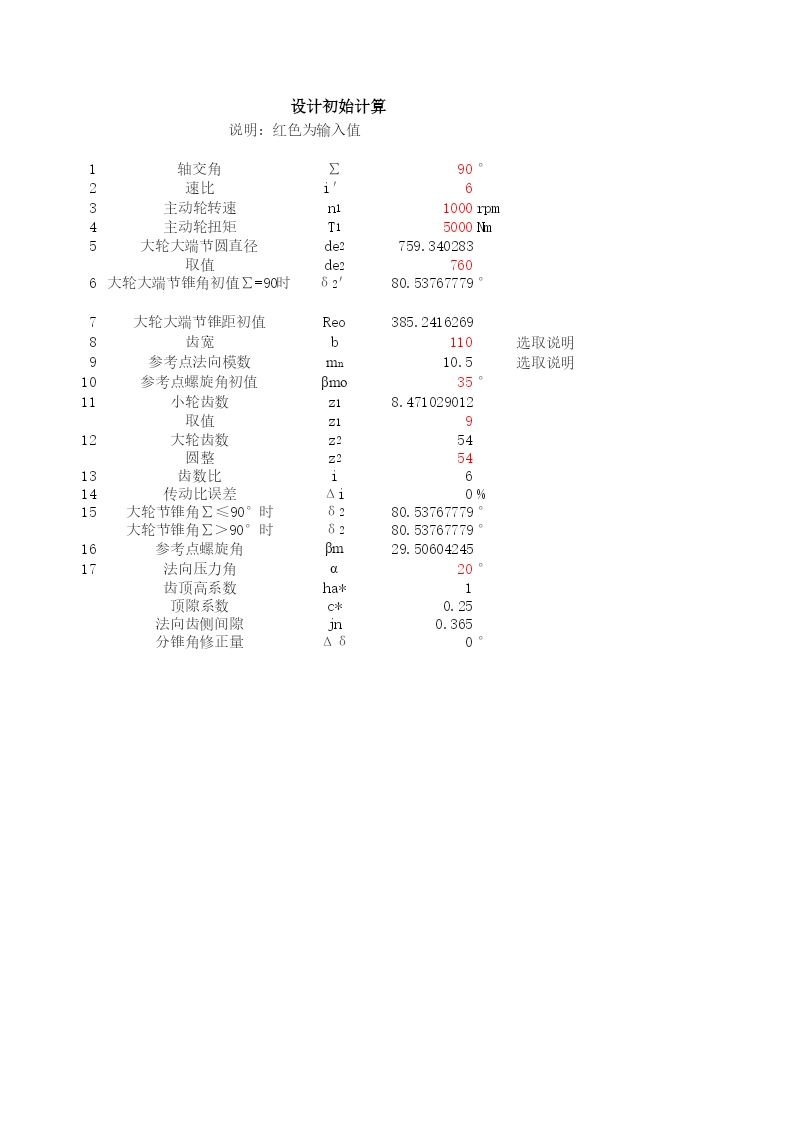

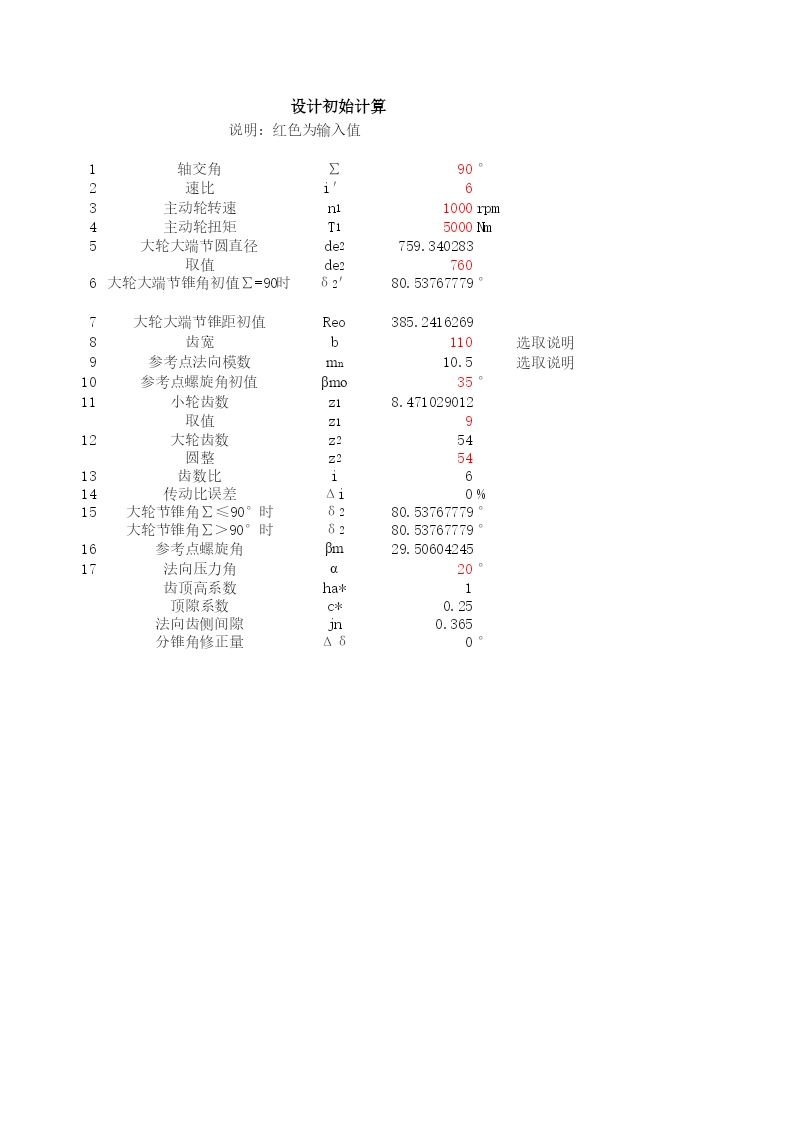

设计初始计算螺旋锥齿轮参数及切齿干涉计算说明:红色为输入值1轴交角∑90°轴交角∑90°ro210刀盘半径2速比i'6压力角α20°zo5刀组数3主动轮转速n11000rpm齿顶高系数ha*1mo10刀具模数4主动轮扭矩T15000Nm顶隙系数c*0.25x10.522360384按等滑动率计算初选参考值5大轮大端节圆直径de2759.340283中点法向模数mn10.5取值de2760小轮齿数z196大轮大端节锥角初值∑=90时δ2'80.53767779°大轮齿数z254中点螺旋角βm30°cosβm

克林贝格螺旋锥齿轮副的油膜特性研究.docx

克林贝格螺旋锥齿轮副的油膜特性研究克林贝格螺旋锥齿轮副是一种新型齿轮副,其应用领域广泛,受到了广泛关注。本文将着重探讨克林贝格螺旋锥齿轮副的油膜特性,并探究其对其稳定性和摩擦学性能的影响。一、克林贝格螺旋锥齿轮副的结构特点克林贝格螺旋锥齿轮副是由主副齿轮、分度圆锥齿轮和超声波换向装置组成的。主副齿轮为螺旋齿,分度圆锥齿轮为球冠齿,通过分野齿与球冠齿的配合,实现了动力传输。此外,超声波换向器可以对齿轮的转速和方向进行精确控制,确保其平稳运行。二、克林贝格螺旋锥齿轮副的油膜形成原理在运行过程中,克林贝格螺旋锥

克林贝格摆线齿锥齿轮基于整体刀盘的切齿加工.docx

克林贝格摆线齿锥齿轮基于整体刀盘的切齿加工克林贝格摆线齿锥齿轮基于整体刀盘的切齿加工摘要:随着工业技术的不断发展和进步,机械传动装置也在不断完善。克林贝格摆线齿锥齿轮作为一种重要的传动装置,在各个领域都广泛应用。而对于克林贝格摆线齿锥齿轮的加工来说,使用整体刀盘进行切齿加工,可以提高加工效率和精度。本论文将探讨克林贝格摆线齿锥齿轮基于整体刀盘的切齿加工的方法和优势。关键词:克林贝格摆线齿锥齿轮;整体刀盘;切齿加工一、引言克林贝格摆线齿锥齿轮是一种广泛应用于机械传动装置中的重要传动装置。其特点是齿轮齿面的曲

基于VBA的克林根贝格螺旋锥齿轮套筒夹具设计.docx

基于VBA的克林根贝格螺旋锥齿轮套筒夹具设计摘要:克林根贝格螺旋锥齿轮是一种常见的机械传动装置,其套筒夹具设计是保证齿轮传动稳定性和可靠性的重要因素。本文介绍了基于VBA的克林根贝格螺旋锥齿轮套筒夹具设计,包括设计初衷、设计过程和结果。通过MATLAB软件对夹具进行优化设计,并在实验中验证了优化结果的正确性,从而为工程实践提供了可靠的理论指导。关键词:克林根贝格螺旋锥齿轮;套筒夹具;VBA;优化设计;MATLAB引言:克林根贝格螺旋锥齿轮作为一种重要的机械传动装置,在航空、机械、船舶等领域得到了广泛应用。

克林贝格准双曲面齿轮齿面建模及接触分析.docx

克林贝格准双曲面齿轮齿面建模及接触分析摘要:本文研究了克林贝格准双曲面齿轮的齿面建模和接触分析。首先介绍了克林贝格准双曲面齿轮的结构特点和应用场景,然后详细描述了该齿轮的几何形状和参数方程式,构建了准双曲面齿轮的三维模型,并进行了接触分析和应力分析。研究结果表明,准双曲面齿轮的设计可以实现更高的传动比和更小的装置尺寸,同时具有较好的齿接触性能和寿命。关键词:克林贝格准双曲面齿轮;齿面建模;接触分析;应力分析;传动比。一、引言克林贝格准双曲面齿轮是一种曲面齿轮,其精度和寿命相对于圆柱齿轮来说更高。准双曲面齿