高磷鲕状赤铁矿中磷矿物的还原焙烧行为及铁磷分离技术的中期报告.docx

快乐****蜜蜂

在线预览结束,喜欢就下载吧,查找使用更方便

相关资料

高磷鲕状赤铁矿中磷矿物的还原焙烧行为及铁磷分离技术的中期报告.docx

高磷鲕状赤铁矿中磷矿物的还原焙烧行为及铁磷分离技术的中期报告摘要:高磷鲕状赤铁矿中的磷矿物具有很高的磷含量,但目前存在分离效率低、尾矿难以处理等问题,限制了其工业应用。本文采用还原焙烧-酸浸分离的方法,系统研究了高磷鲕状赤铁矿中磷矿物的还原焙烧行为及铁磷分离技术。研究结果表明,高磷鲕状赤铁矿中的磷主要以草酸铁矿物、磷灰石和含磷铁矿物形式存在,并且磷灰石和含磷铁矿物的还原焙烧性能相对较好。在还原焙烧过程中,磷灰石和含磷铁矿物可以很好地被还原,磷主要以气态P2O5的形式释放出来。而草酸铁矿物的磷则较难被还原,

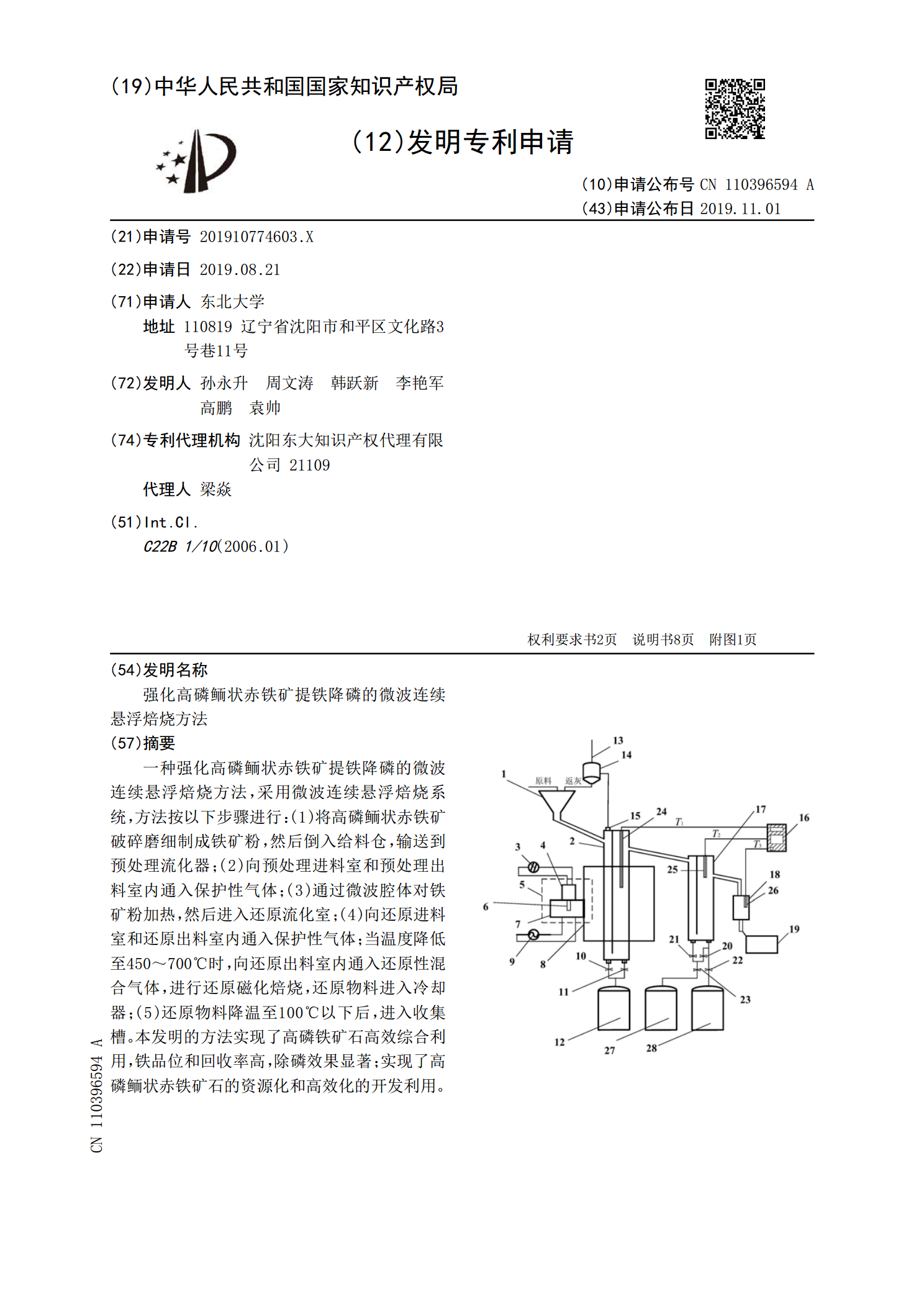

强化高磷鲕状赤铁矿提铁降磷的微波连续悬浮焙烧方法.pdf

一种强化高磷鲕状赤铁矿提铁降磷的微波连续悬浮焙烧方法,采用微波连续悬浮焙烧系统,方法按以下步骤进行:(1)将高磷鲕状赤铁矿破碎磨细制成铁矿粉,然后倒入给料仓,输送到预处理流化器;(2)向预处理进料室和预处理出料室内通入保护性气体;(3)通过微波腔体对铁矿粉加热,然后进入还原流化室;(4)向还原进料室和还原出料室内通入保护性气体;当温度降低至450~700℃时,向还原出料室内通入还原性混合气体,进行还原磁化焙烧,还原物料进入冷却器;(5)还原物料降温至100℃以下后,进入收集槽。本发明的方法实现了高磷铁矿石

两段焙烧-磁选-浸出高磷鲕状赤铁矿提铁降磷的方法.pdf

一种两段焙烧‑磁选‑浸出高磷鲕状赤铁矿提铁降磷的方法,包括以下步骤:(1)准备高磷鲕状赤铁矿;(2)破碎后磨矿至粒径≤0.074mm的部分占70~80%;(3)送入焙烧炉在1000~1200℃条件下焙烧5~30s;(4)送入磁化焙烧炉,在还原气氛条件下加热至500~650℃焙烧;(5)磨矿至粒径≤0.038mm占40~70%,然后进行弱磁选;(6)用硫酸进行酸浸脱磷,过滤分离出的固体物料水洗烘干。本发明的方法实现了高磷鲕状赤铁矿高效综合利用,铁品位和回收率高,除磷效果显著,实现了高磷鲕状赤铁矿石的资源化和

一种高效去除高磷鲕状赤铁矿中磷的方法.pdf

本发明涉及高磷鲕状赤铁矿脱磷技术领域,尤其是一种高效去除高磷鲕状赤铁矿中磷的方法,通过对鲕状赤铁矿压制成球后,置于真空碳管炉中,加热,真空还原处理30?60min,收集固相,使得得到精矿的磷含量低于0.1%,精矿的品位达到60%以上,并避免了采用脱磷剂的处理,降低了处理成本,避免了新物质的加入,降低杂质成分。

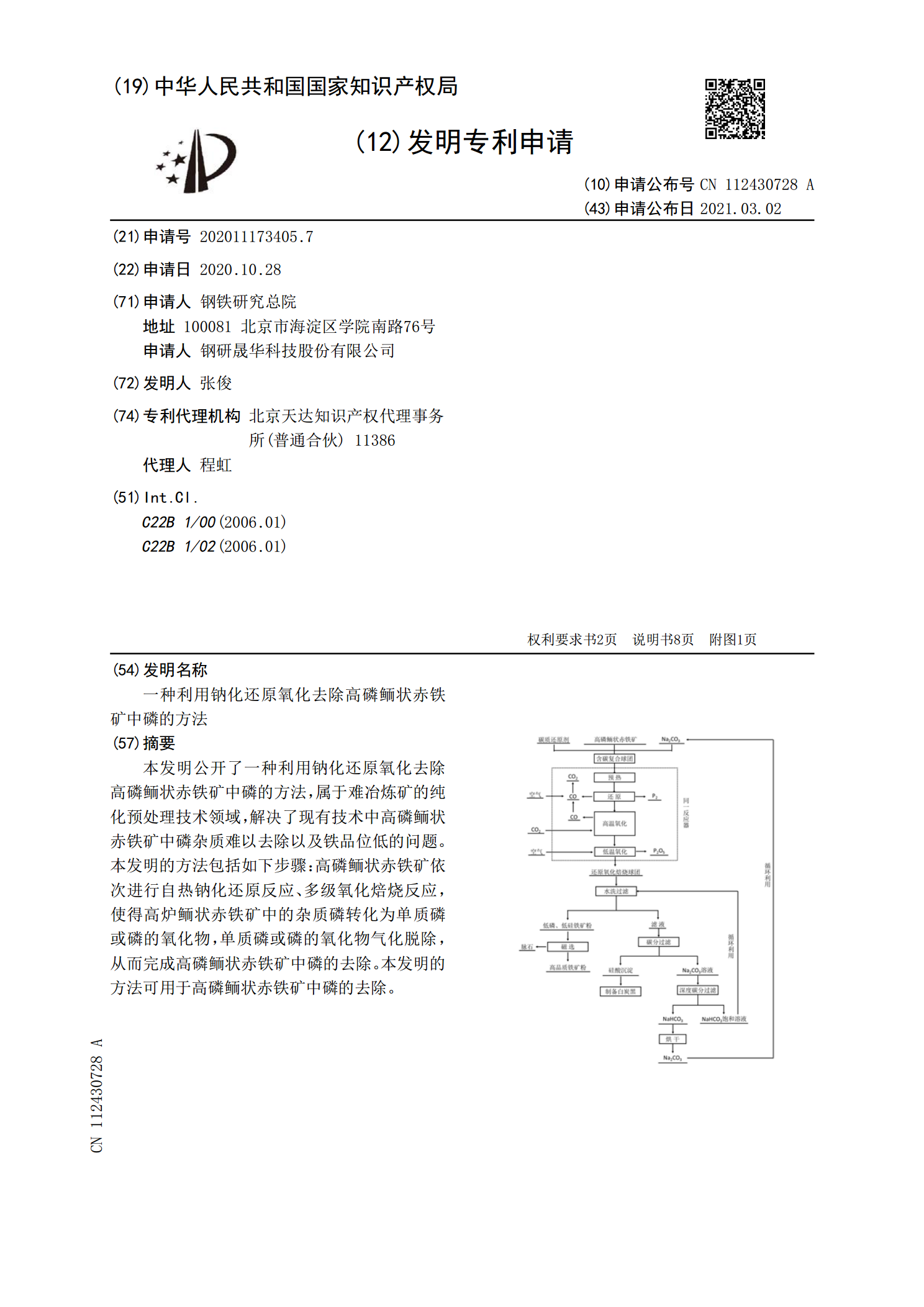

一种利用钠化还原氧化去除高磷鲕状赤铁矿中磷的方法.pdf

本发明公开了一种利用钠化还原氧化去除高磷鲕状赤铁矿中磷的方法,属于难冶炼矿的纯化预处理技术领域,解决了现有技术中高磷鲕状赤铁矿中磷杂质难以去除以及铁品位低的问题。本发明的方法包括如下步骤:高磷鲕状赤铁矿依次进行自热钠化还原反应、多级氧化焙烧反应,使得高炉鲕状赤铁矿中的杂质磷转化为单质磷或磷的氧化物,单质磷或磷的氧化物气化脱除,从而完成高磷鲕状赤铁矿中磷的去除。本发明的方法可用于高磷鲕状赤铁矿中磷的去除。